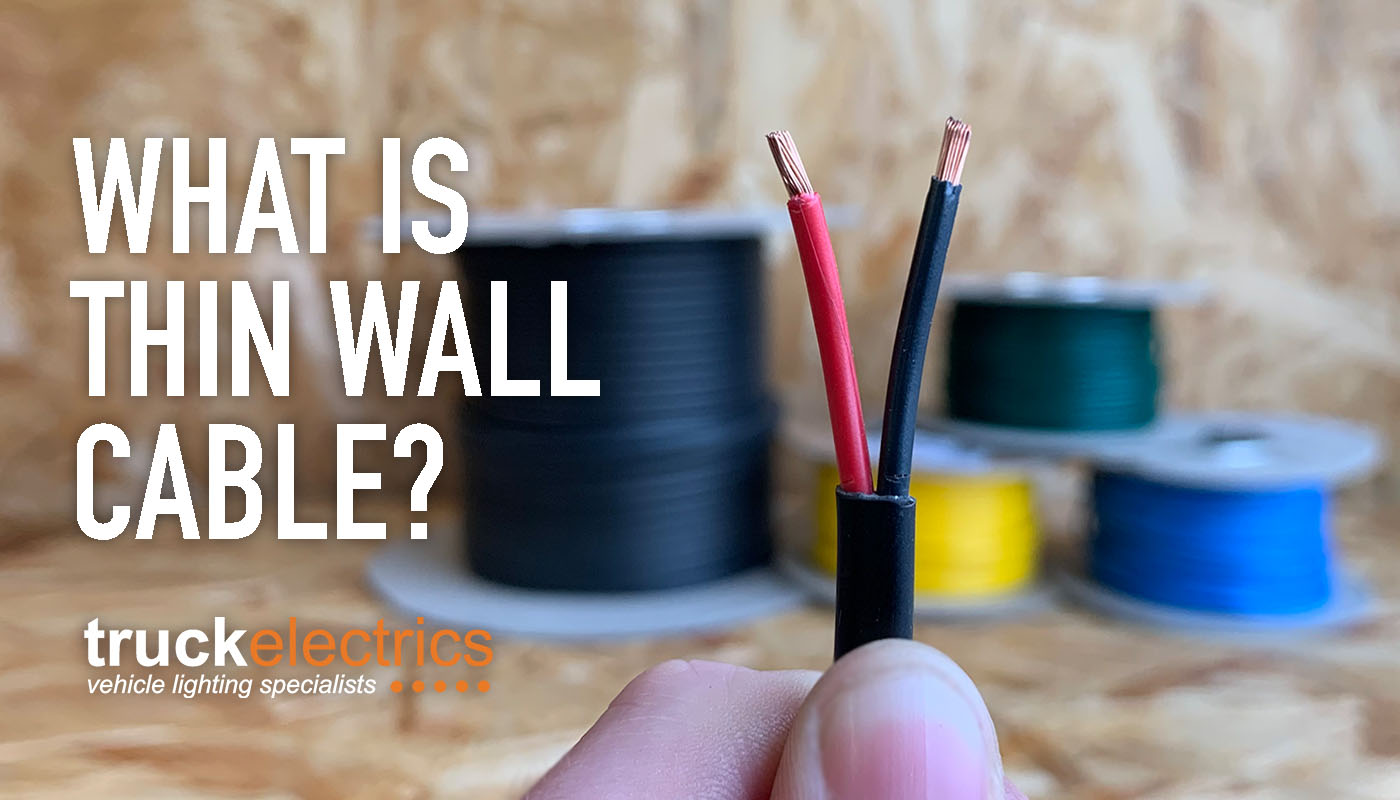

Thin wall cable is a low voltage cable used primarily in the automotive and marine industries. It is constructed from a stranded copper wire centre encased within a hard grade PVC insulating sheath. This thin wall design offers some key advantages over standard automotive electric cable. It is often the preferred choice for mechanics when it comes to auto and marine electrical work.

- Four Core Thin Wall Cable

Advantages of Thin Wall Cable:

Thin wall cable, (also known as thin wall wire or thin electrical cable), holds a number of key advantages in terms of performance when compared to standard pvc cable. Firstly, thin wall delivers a higher current capacity carrying capacity than standard cable. Secondly, the reduced thickness of the pvc insulating sheath delivers advantages when it comes to weight and volume. This means the vehicle will benefit from a lighter load and the reduced volume means the cables do not require the same amount of space when being installed in areas of restricted room. The reduced weight is of particular benefit when it comes to large cable harnesses. For these reasons thin wall cable is often the first choice of electrical cable used by the major global car manufacturers.

Excellent Physical Characteristics:

In addition to the performance advantage of automotive thin wall cable, (current carrying capacity and weight benefits), it also delivers crucial physical attributes that are essential in the challenging environment of an automotive vehicle. Hard grade pvc insulated thin wall cable demonstrates excellent acid, oil, petrol and diesel resistance making it suitable for both auto and marine applications. It also shows great abrasion resistance making it a robust and hard wearing cable choice. It is suitable for use across a wide temperature range, (-40º Celsius to +105º Celsius), standing up to extremes of cold and hot environments. Thin wall insulation automotive grade electrical wire is suitable for a wide range of automotive applications.

Typical Thin Wall Applications:

Thin wall automotive cable is commonly used for low tension electrical wiring jobs. It can be commonly found in automobile, motorcycle and marine electrical cabling. It is ideal for use in the following applications: engine starting, charging, signalling and lighting. Thin electric cable can also be applied to instrument panel circuits. The flexible and flame retardant nature of the cable makes it a suitable choice for this wide range of applications and environments. Thin electrical wire / thin cable is available in single, twin, 3, 4, 5 and 7 core variants.

Installation & Handling Benefits:

The benefits of thin wall cable are also found during installation. Thin wall cable is easier to handle and install when making connections. Due to the fact that the cable is lighter and has a reduced size it is easier to manually handle and transport. It is also highly flexible which means that as the cable is bent and manipulated the insulating sheath does not crack or shear. This makes it much easier to manipulate the cable when working with bundles and feeding it through confined spaces and ducts.

- Shop Thin Wall Cable: Here

Precision Engineering Saves Time & Money:

Because thin wall is a precision engineered cable product all its strands and insulating sheath have been produced to highly accurate specifications. This results in a cable that is much easier to strip and crimp. The ease of installing connections coupled with the light weight, highly flexible bundling characteristics of thin wall deliver real world benefits and savings when it comes to time and money.

- Shop Truck & Trailer Accessories Now: Click Here